The importance of applying the correct video sync signal to your TV, monitor, scan converter, HDMI adaptor or projector.

This post tries to answer some of the many questions I get relating to the GBS-8200 and non-standard video types. I will

provide information on how to help identify the correct synchronisation or sync signal for shortness, for common applications

and describe some of the effects you may see when you get it wrong. I do not have a guaranteed fix for any problem, this is more

a how to guide to help you fix any issues you may encounter.

Topics covered in this post

What are synchronisation(sync) signal(s)?

Understanding your composite from your H/V and Sync On green type?

Basic information on video sync timings, PAL, NTSC, CGA, EGA, VGA.

Converting video sync amplitude

Sync strippers/cleaners/separators

Best options for the GBS-8200

What are synchronisation(sync) signal(s)?

Let’s start with a basic description of a sync signal. I took the following from the Tektronix Video Measurements glossary:

Sync – a) Abbreviation for synchronization. Usually refers to the synchro-

nization pulses necessary to coordinate the operation of several intercon-

nected video components. When the components are properly synchro-

nized, they are said to be “in sync”. b) Signals which control the sweep of

the electron beam across the face of the display. The horizontal sync, or

HSYNC for short, tells the display where to put the picture in the left-to-

right dimension, while the vertical sync (VSYNC) tells the display where

to put the picture from top-to-bottom. c) The portion of an encoded video

signal which occurs during blanking and is used to synchronize the opera-

tion of cameras, monitors, and other equipment. Horizontal sync occurs

within the blanking period in each horizontal scanning line, and vertical

sync occurs within the vertical blanking period.

With the move to LCD displays we are not concerned with movement of an electron beam but it is useful to understand how

the horizontal and vertical sync signals play their part in creating the display you see.

Basic information on video sync timings, PAL, NTSC, CGA, EGA, VGA.

| Video type |

Horizontal

frequency |

Vertical

frequency |

Interlaced? |

Number

of lines |

Notes |

| PAL |

50 Hz |

15.625 KHz |

Yes |

576 active |

(1) |

| NTSC |

59.94 Hz |

15.750 KHz |

Yes |

480 active |

(1) |

| CGA |

60 Hz |

15.750 KHz |

Yes |

200 |

TTL signals. (2) |

| EGA |

60 Hz |

15.750 KHz/21.80 KHz |

No |

350? |

Vertical frequency changes depending on the mode,

200 line display is 15.750KHz, 350 line display is 21.80 KHz. TTL signals |

| VGA |

60 Hz |

31.469 KHz |

No |

480+ |

Lowest resolution shown, extends up to 2014×1536 |

(1) Quite often when a system states PAL or NTSC output, e.g. a camera, the signal is a composite video signal. For higher quality

conversions, either a Y/C(S-video) or an RGB output is preferred. The sync is embedded with the video.

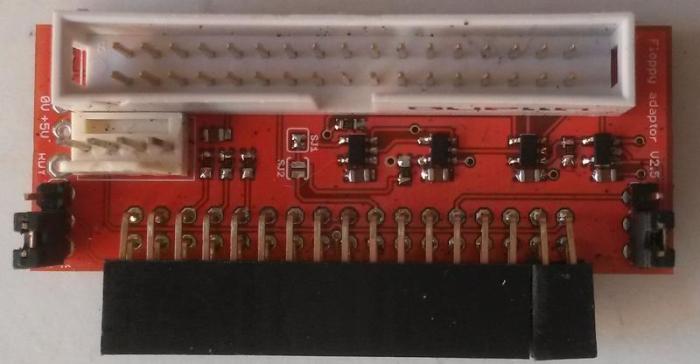

(2) CGA is unique in that it uses TTL digital signals, with an intensity pin to get 16 colours. If you don’t have an adaptor board to convert

the RGB+intensity to analogue, most converters will struggle. Has separate H/V syncs

You will note that I state that NTSC has a vertical frequency of 59.94 Hz, where as most of the other standards are 60Hz, indeed some

literature states 60 Hz for NTSC. In practice, most of the time this 0.06Hz deviation makes no difference.

Understanding your composite from your H/V and Sync On green type?

So you have a retro game console or computer and you want to connect it to a modern LCD display or a projector, should be straightforward right?

Depending on the equipment you may have a single signal or multiple types. The table below details the main types:

| Sync type |

Voltage |

Description |

| Composite video |

1V |

Normally a yellow plug, contains video and a combined sync. Used by SCART inputs. |

| CSYNC |

TTL (2-5V signal) |

Output by some graphics cards or a TTL signal from retro equipment. It only contains timing information, no video. |

| HSYNC |

TTL (2-5V) signal |

Provides the horizontal video timing, which details the start and end of a line. |

| VSYNC |

TTL (2-5V) signal |

Provides the vertical sync timing, which describes the frame rate. |

| Sync-on-green |

1V |

A -0.3V sync signal attached to a 0.7V peak green video signal. |

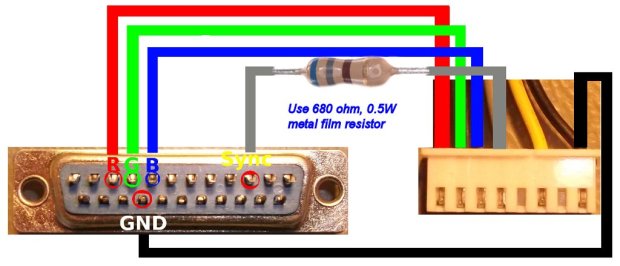

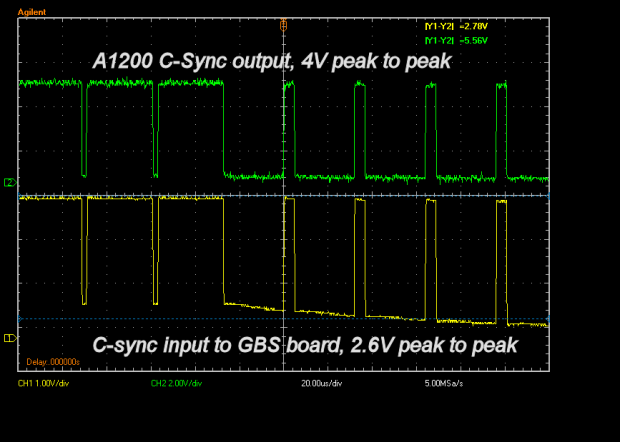

An important point is that you need to know what signal amplitude is expected by your TV/monitor/scaler/converter. A common mistake, is to connect

a CSYNC signal, either from a retro device or a computer, to a SCART socket. The SCART standard expects composite video on pin 20, if you feed in a

TTL CSYNC signal, you could be supplying a signal upto 5x higher than expected. My Amiga SCART and Atari SCART cables fixed multiple video issues,

with a simple fix to the sync amplitude, by adding a series resistor on the sync signal.

I show a TTL signal as a 2-5V signal, for good reason. A retro computer or video system will have 5V logic, a logic 1 output can be from 2.4V (min) to 5.5V(max).

When you connect one of these signals to a 3.3V video chip, like that on the GBS-8200, you are damaging the device as the input signal exceeds the supply voltage.

The ESD protection diodes conduct and soft of allow the system to work, but they are not meant to be used continuously and will fail, at the same time as your board.

The next section details various methods of converting sync signals.

Converting video sync amplitude

So how do you convert a composite video to separate h/v sync or reduce a 5V TTL signal to 3.3V LVTTL or any or a number of options?

Some conversions are simple and can use readily available modules, others need a little circuit board. The table below will help:

| From |

To |

Solution |

| Composite |

CSYNC (3.3V or 5V) |

Sync stripper |

| Composite |

H & V Sync (3.3V or 5V) |

Sync stripper2 |

| CSYNC |

Composite (1V) level |

Resistor circuit |

| H & V Sync |

CSYNC (3.3V or 5V) |

OR/XOR gate |

| Sync on green |

CSYNC (3.3V or 5V) |

Sync stripper2 |

| Sync on green |

H & V Sync ((3.3V or 5V) |

Sync stripper2 |

| 5V TTL |

3.3V TTL |

Level converter |

Examples of each circuit element are shown in the sections below. What is not shown are power supplies and connectors. This is left to the developer,

though for all circuits shown, a simple linear regulator would suffice.

Sync strippers/cleaners/separators

When I first started researching video adaptors and converters I came across ‘sync strippers’ and wondered what they were. They are relatively simple

circuits, based around commonly available sync separators, the most widely used being the National Semiconductor (now Texas Instruments) LM1881.

They accept a composite video signal and strip the colour burst off the signal and in the case of the LM1881, output a 5V TTL CSYNC signal.

Syncstripper circuit

Taken from the LM1881 datasheet. Widely used as it’s a readily available part in a DIP package.

There are two limitations of this part:

1) The 5V TTL output is not compatible with modern TVs/HDMI adapters/projectors. It needs a level translator.

2) It does not provide a separate horizontal sync output. If your adaptor only needs CSYNC, great, otherwise try the Syncstripper2 circuit below.

You may get away with using CSYNC for HSYNC but it is by no means guaranteed.

Syncstripper2 circuit

Again taken from the datasheet. Being a surface mount device will put some people off, the VSSOP-10 package is a bit small but you can

easily buy a SSOP to DIP adaptor off ebay. If you power it from a 3.3V supply, the logic level outputs will be compatible with modern

display devices, no external converter needed. It provides true H/V and C sync outputs and works with a wider range of video types and frequencies.

Would an adaptor board with this circuit, video amplifier and maybe a scanline generator be of interest?

Potential divider and logic level converters

Resistive potential divider circuits

The first circuit converts 5V TTL signals to 1V CSYNC for SCART

This is a simple potential divider circuit. The output voltage is 75/(75+330) x Vin which gives an output voltage that is ~18% of the

input or around 0.92V.

The second variant is for the GBS-8200 or a modern monitor that is not 5V tolerant.

With a VESA VGA video monitor or equivalent, the input impedance of the display is much higher, in this instance, 2K. As the aim is to

reduce the signal to be approximately 3.3V, we reduce the amplitude by 27-30%.

One disadvantage of this circuit is that the RC time delay does affect the rising/falling edge of the sync pulse slightly. In most circumstances,

this will not matter but some systems may have issues if the time delay extends past a 100ns rise/fall time. For a cleaner, faster signal, use

logic devices.

Transistor logic level convertor

An improvement is to use a transistor circuit.

This circuit is simple to implement and provides faster edges than resistor networks. You will also find this on ebay as a

level translator for the Arduino, it is acceptable to use it for video.

OR/XOR sync combiner circuit

The circuit shown above has the option to use either an OR gate or an XOR gate to combine separate HSYNC and VSYNC into a CSYNC signal.

Most of the time, the OR gate will suffice. Depending on the display you interface, you may need to invert the vertical syn portion,

hence the option to use an XOR gate. The 33R resistors were added to damp any ringing when driving long cables. With careful selection of the logic

family, you can use a 5V tolerant part, operating from a 3.3V supply.

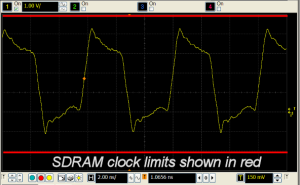

Effect of supplying a 5V signal to a 3.3V device

This could be very detailed and lengthy discussion detail the effects of electromigration and it’s detrimental impact on device reliability. I’ll summarise,

DON’T CONNECT 5V LOGIC TO MODERN MONITORS OR ADAPTORS!

Whilst it will appear to work, you may see odd effects, occasional display artefacts or issues displaying a stable image occasionally. If a device is powered

from 3.3V and you feed in 5V, you are exceeding the power supply by upto 1.7V, not a good start. The internal ESD protection diodes, will clamp the signal

to around 3.9/4.0V, which you might think is OK. The clamping action distorts the signal and can cause the video display/adaptor to incorrectly sample the sync signal.

The ESD diodes are only meant to have short term use to protect from static electricity, which is normally a short, sharp shock. If they are continuously used, they

will fail and when they do, the full 5V signal is fed into the IC. Depending on many factors, the distortion will get worse but one thing is 100% certain, the device will fail.

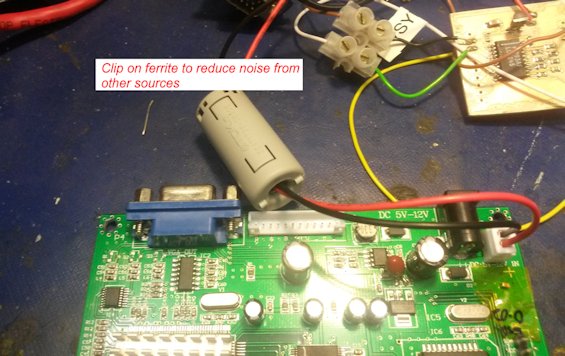

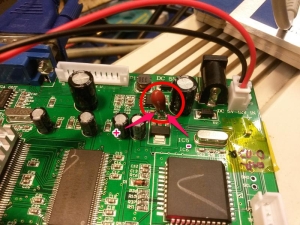

Best options for the GBS-8200

I would recommend as a minimum that any sync signals are scaled using at least a potential divider circuit or a transistor level shifter as they are readily

available, providing your source produces a C sync signal. If you need to to combine H and V Sync, use the logic circuit shown above.

If your system provides a composite video signal, use one of the sync strippers but ensure you condition the output to be 3.3V LVTTL compatible.

Summary

I hope this guide has been useful and informative. It is only meant to provide guidance on common issue I have encountered when inter-connecting various video

systems it is not a definitive guide of what you must do. Sometimes you need to experiment, if you have an oscilloscope, make some measurements.

I’ll be taking a break for a bit whilst I get busy with the CAD tools but I will read and respond to your comments.